Streamlined our operation saving more than 40% in labor costs

GMNAC PFEP Job

saved 40%

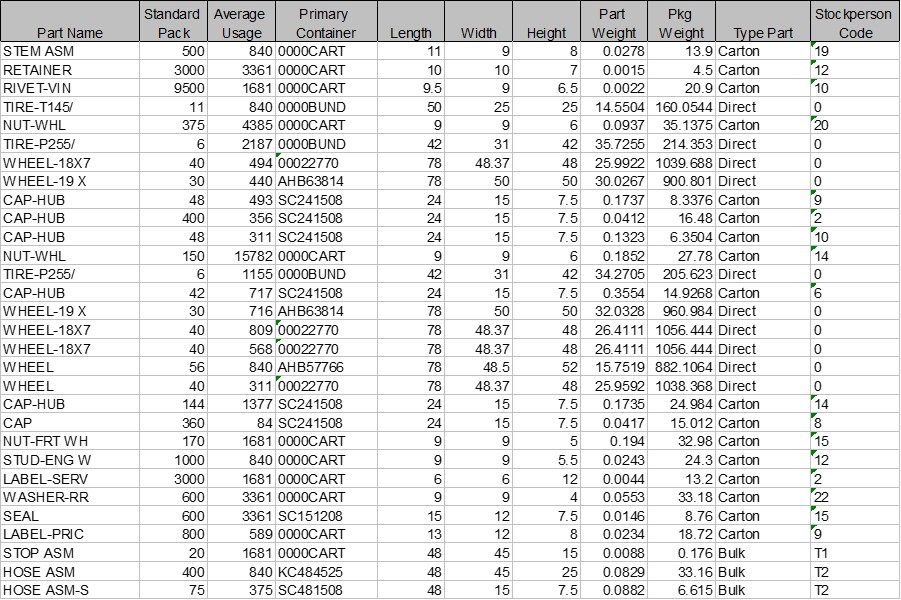

The Magnys Plan For Every Part (PFEP) program provided GM with instant access to up-to-date information on every part that fed into 26 manufacturing facilities –from a component’s dimensions and manufacturing source, to how and where it ships, as well as all relevant supplier contact information and Magnys accomplished this using fewer people than GM had historically used. Magnys PFEP allowed GM to know at any time how many parts had been validated for a vehicle program, how many were in process and how many parts had not yet been contracted. With this information, GM identified potential problems at a much earlier stage, eliminating the need to rush engineering teams to supplier plants deep into a launch. The result was a streamlined planning process. The Magnys PFEP team improved the quality of information at a savings of more than 40% compared to past expenditures. This is another example of how we add value to our customers’ manufacturing operations.