Saw a significant reduction in launch costs at an accelerated timeframe

Large Tractor Manufacturer

Significant reduction in launch costs

Tractor manufacturer partners with Magnys on New Product Programs

When a Large Tractor manufacturer realized they were facing significant challenges launching new products, they decided to go outside of their organization for engineering services expertise on New Product Programs.

Their management turned to Magnys Innovative Solutions to help them with plant layouts, program management and material planning. Their goal was improved operational efficiency, reduced logistics costs, reduced assembly process times, improved quality, lower launch costs and increased production.

The Magnys team first set out on a fact finding mission to study and fully understand the overall program objectives, from project management to engineering to the plant floor. Thru collaborative meetings, Magnys got involved in an ongoing New Product Launch already underway. Magnys provided Database Development, Material Planning, Auditing and New Plant Layouts.

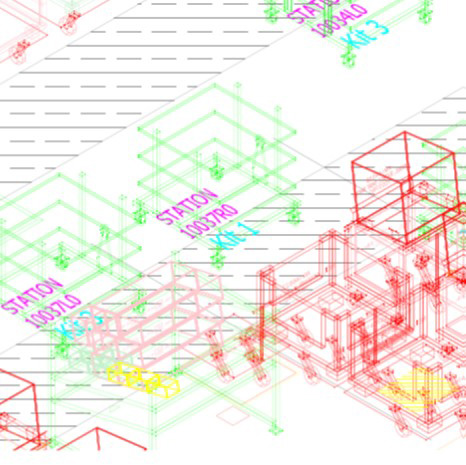

Magnys seamlessly integrated within their ME team to manage Layout Development thru out the design process. Magnys utilized ACAD & FactoryCAD which included all Materials, Equipment, Facilities, & Utilities in a 3D Environment. Magnys developed multiple M.S. Access databases to keep up with continuous product changes as the program progressed. In addition, Magnys interfaced with the materials team to “right size” each container in support of the PFEP process. This highly detailed process resulted in accurate material placement to support a quick launch.

Magnys also provided the Scope of Work and Layouts needed to competitively bid the project by outside contractors. During the launch Magnys remained on the “shop floor” to coordinate the implementation of equipment & utilities required to set up the new assembly line. Magnys personnel reduced launch timing, resulting in more uptime, which resulted in increased revenue.

The results of the program were remarkable. During the 3 year process that spanned 3 facilities and touched over 10,000 part numbers, the Magnys team easily met the program goals and did so in an accelerated time line. The company saw a significant reduction in launch costs and reduced the quantity of personnel required to manage and deliver materials. Another key success factor in the smooth launch was the ability to validate system alignment. This ability is a key requirement to remain a “Lean” process.

Due to the successful results of this initial project, Magnys was asked to remain on-site and develop future state layouts for upcoming New Product Programs.

To learn more about how Magnys can help your company, please contact info@magnys.com.